Recently, under the requirements of relevant national policies, the normalization of nucleic acid requirements has been gradually canceled, and the majority of residents are responsible for their own health. The domestic demand for antigen detection kits has surged.

The Covid pandemic is still going on, and there may be a peak of infection in the future. While the supply of antigen reagents is in short supply, it will also produce a large amount of disposable medical waste.

COVID-19 testing cannot be reduced nor avoided, so what can we do to reduce the pressure of medical waste on the natural ecological environment?

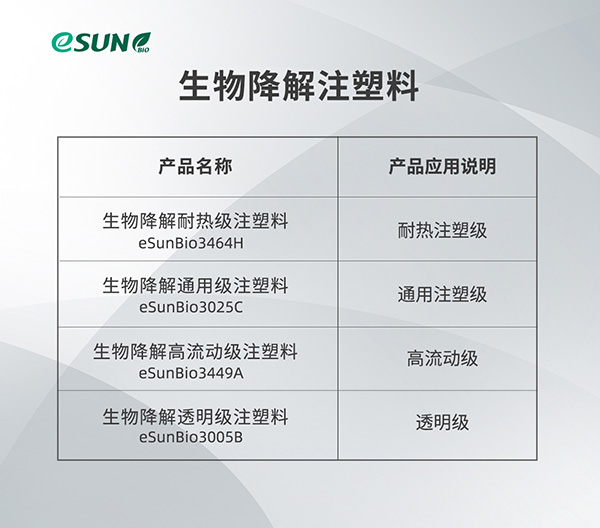

The global “plastic ban and restriction” has promoted the application of biodegradable materials in various industries and fields. In 2021, eSUN biodegradable materials and modified materials will be shipped in large quantities, providing strong support for the upgrading of plastic products in various industries. In addition to its application in catering, packaging and other industries, biodegradable injection plastic has also expanded its application in medical packaging materials. It can be used to make environmentally friendly and biodegradable COVID-19 test kits. In the long run, it is of great significance for ecological environment protection and green and healthy economic development.

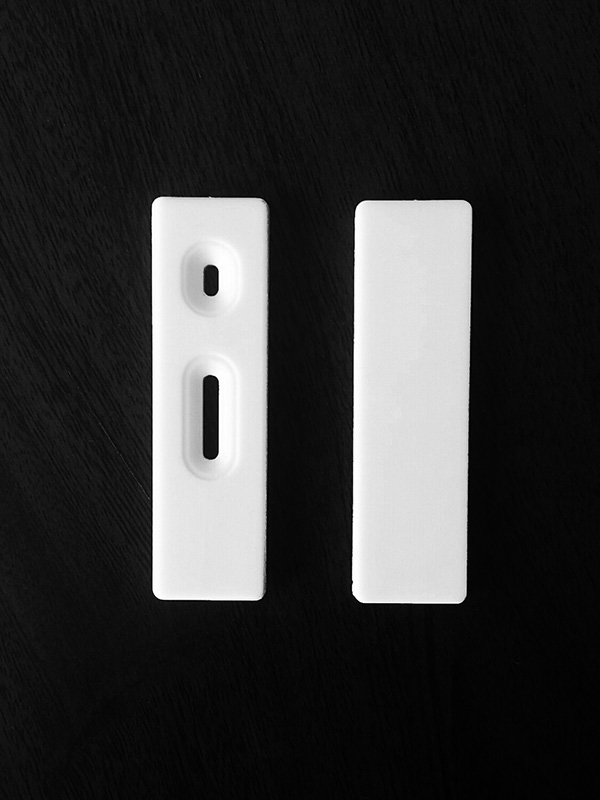

Degradable Covid detection kit

eSUN biodegradable injection molding materials have a wide range of applications, and the application scenarios are still expanding.

1. Product grade

2. Product Features

① Non-petroleum-based biological materials, low-carbon environmental protection, renewable resources, saving oil resources;

② Good mechanical properties, high rigidity, and impact resistance;

③ Good processing performance, wide process range, easy to form, continuous nozzle, fast cooling and setting, easy to demould;

④The surface gloss of the product is good;

⑤The product has a low shrinkage rate and good dimensional stability;

⑥Can resist various solvents, easy to color or print.

3. Product application

Biodegradable injection plastics are mainly used in products made by general injection molding methods, and can be used in many fields such as electronic and electrical products, catering supplies, stationery, daily-use products, cosmetics, mechanical engineering parts, toys, and automobiles.

With the vigorous promotion of global plastic prohibition and restriction, the application scope of biomaterials still has much room to expand. If you have any needs, please contact us through the following ways.